E36 Turbo Guide

Overrun Tuning specializes in making your BMW fast. This guide will give you all the information you need to start your E36 turbo build.

This guide will be broken down into the following sections,

Block+Head

This section will highlight the differences between the engine blocks and heads.

Exhaust

This section will cover turbo selection, exhaust manifold options and hot side piping.

Intake

This section will cover the intake manifold, fueling, intercooler and cold side piping.

Electronics

This section will cover the electronics, wiring, sensors and engine management options.

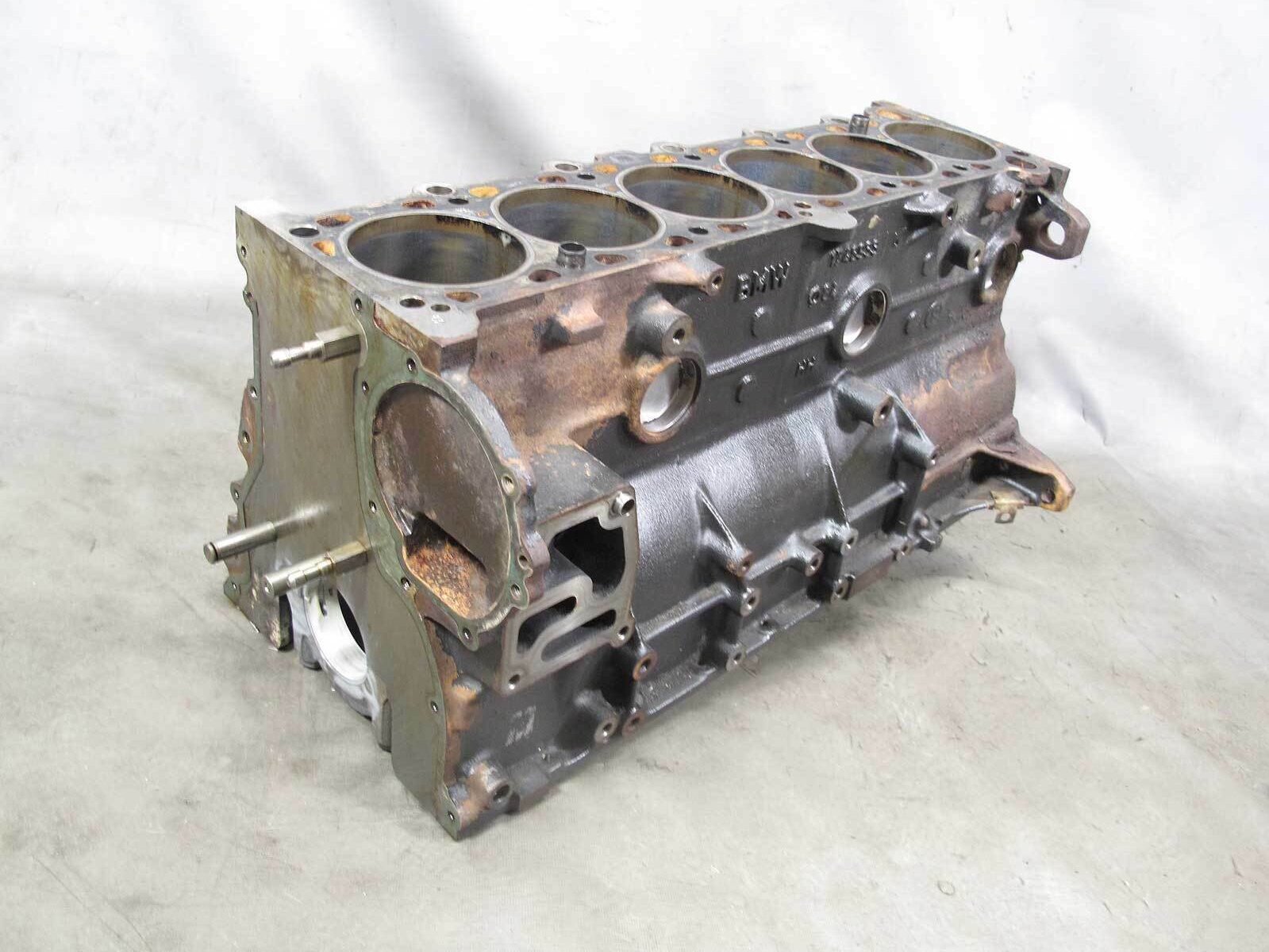

Block

M52 Aluminium Block

All M52 blocks in Australia are made out of aluminium. In some rare cases, certain castings came with steel sleeves - they are incredibly rare to find. The large majority came with Nikasil coated cylinder liners.

The main weaknesses of the aluminium block are the threads and cylinder wall wear. The threads for the head bolts commonly strip clean upon removal. The Nikasil liners often wear out and as a result the cylinder walls become uneven - typically rendering the block useless.

Recommended Upgrades for Boost

Use head studs instead of bolts - do NOT use ARP M50/M52 head studs they are not right length - use Raceware M52TU/M54 head studs.

Time-Sert the head bolt threads

Drill and tap to M12x1.5 (from M10) and use larger studs

If using a 3.0L 89.6mm stroke crank or plan to increase the rev limit drastically 7200RPM+, consider installing an oil chain tensioner. This reduces the slack and vibrations of the chain rattling the oil pump nut loose at high RPM.

M50 Iron Bock

The M50 iron block is the ideal block for boosted builds. There are two varieties of the M50 iron block, the M50B20 and M50B25. The major difference is the bore diameter - 80 vs 84mm respectively. Unfortunately, the M50B20 has a different casting and the cylinders cannot be bored out to 84mm reliably.

M50B25 and M50B25TU have essentially the same blocks, with some early M50B25NV blocks coming with a oil pump chain tensioner from factory (rare).

Recommended Upgrades for Boost

Use ARP head studs - beware of fakes! Easily identifiable by the price difference.

If going for big power, consider drilling and tapping to M11 and use S54 ARP head studs.

If using a 3.0L 89.6mm stroke crank or plan to increase the rev limit drastically 7200RPM+, consider installing an oil chain tensioner. This reduces the slack and vibrations of the chain rattling the oil pump nut loose at high RPM.

Rotating Assembly

M52 Alloy

Safe HP Limit

M52B25: 400HP

M52B28:450HP

Weaknesses

Skinny/weak factory rods

Ring lands breaking due to detonation

Head lifiting/head gasket seal

M52B25: Small displacement resulting in more turbo lag.

M52B25: Cast Crank

M50

Safe HP Limit

M50B25 Non-Vanos: 550HP

M50B25TU:500HP

Weaknesses

M50B25TU has skinner rods than NV, however thicker than M52

Ring lands breaking due to detonation

Small displacement resulting in more turbo lag.

Cast Crank

Forged Rotating Assembly

Safe HP Limit

M5xB30: 800HP

M5xB28:750HP

Requirements

Forged Rods with ARP Rod Bolts

Forged Pistons 84.5mm Bore, ~9.0C/R for pump gas, ~10.0 C/R for E85

ATI Damper if revving over 7000 RPM

M54B30 Rotating Assembly

Safe HP Limit

M54B30:550HP

Weaknesses

Skinny/weak factory rods

Ring lands breaking due to detonation

Thin pistons prone to heat

Head

The M50NV/M50TU/M52 heads are all interchangeable between M50 and M52 blocks. The general casting is the same however with differences in the valvetrain.

M52 Head

Valve Springs: Single Conical

Valve Stem: 6mm

Lifter Diameter: 33mm

VANOS: Yes

Valve Cover: Early M52s came with Magnesium valve covers - essential as it prevents the downpipe from melting the valve cover on top mount setups. The majority came with plastic valve covers.

Ignition Coils: Not exchangeable with M50NV/TU

M50 Head

Valve Springs: Single Cylindrical

Valve Stem: 6mm

Lifter Diameter: 35mm

VANOS: Yes

Valve Cover: Magnesium

M50 Non-Vanos Head

Valve Springs: Double Cylindrical

Valve Stem: 7mm

Lifter Diameter: 35mm

VANOS: No - The VANOS unit can be retrofitted, the VANOS mounting area needs to enlarged to fit the mechanism.

Valve Cover: Magnesium

Head Gasket

For all boosted applications the only head gasket that should be is a copper cut-ring style headgasket. Athena/JE make them with various bore diameters at 2mm thickness. The cut-ring head gasket reinforces the seal between the head and the cylinder.

MLS head gaskets come in different thicknesses to lower or increase compression ratio - however they are not recommended as they have sealing issues. MLS head gaskets requires the head and block surface to be perfectly flat in pristine condition.

For low boost, the stock headgasket will suffice provided the head bolts are upgraded to studs - can be done with the head still attached to the block.

Exhaust

The Turbo

The recommended turbo size is directly correlated to the displacement size of your engine. For those aiming for 15psi or below, consider turbos with internal wastegates - less plumbing and saves you the cost of a wastegate. Never ever use a cheap/replica/fake external wastegate!

2.0-2.5L: Garrett GTX3071R, GTX3076R, G30-770 or similar

2.8-3.2L: GTX3076R, GTX3582R, GTX3584RS, G35-900, G35-1050 or similar

For those looking at breaking the 1000whp mark, GTX42/G42 or larger turbo is required.

Exhaust Manifold

Fear no more - Overrun Tuning has the solution to the trickiest part of any RHD E36 turbo build: the exhaust manifold and downpipe.

Overrun Tuning has worked with K64 Performance to bring you a headache free, direct bolt on exhaust manifold and downpipe kit (Yes - that is an Overrun built engine as the featured photo for the RHD manifold kits). Now with an option to retain AC with custom lines. Picture on the right is the standard tubular manifold with 2.75 to 3 inch downpipe. Contact us today to order your manifold kit - our pricing is unmatched.

Manifold Flange Options: T3/T4/V-Band

Downpipe Flange Options: Garrett 4 or 5 bolt/V-Band

Wastegate Port: 50mm

Turbo Oil + Coolant Lines

Turbo Oil Feed: Oil for the turbo is provided from the VANOS line on the oil filter housing, use this custom Rally Road banjo bolt.

Turbo Oil Return: The oil return is a gravity return from the turbo to the bottom left of the front timing cover. A fitting can be installed here - see photo to the left.

Turbo Coolant Feed and Return: Remove the coolant lines for the throttle body and plumb them to the turbo. The throttle body does not need to be cooled.

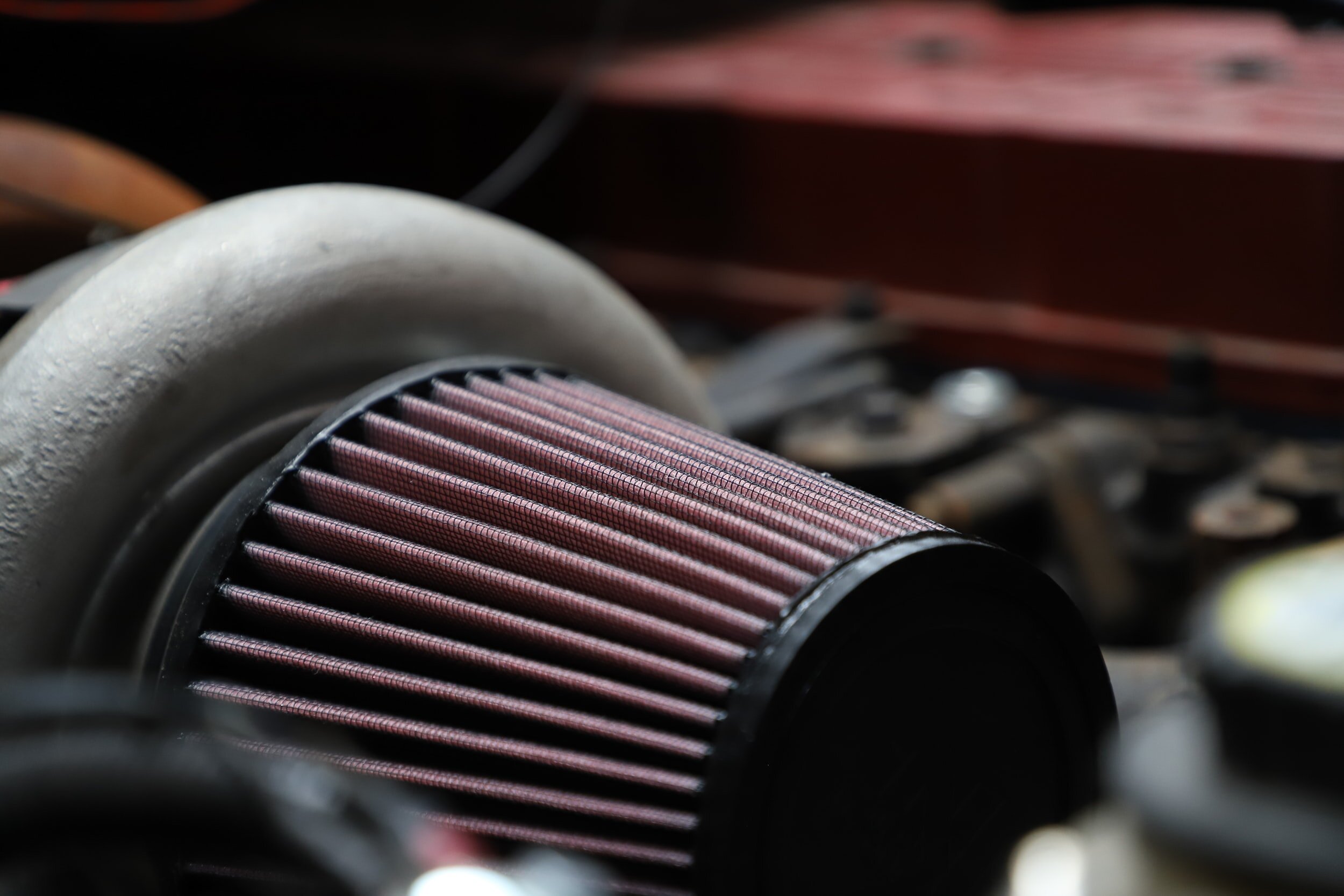

Intake

Intake Manifold

The preferred OEM intake manifold is the intake manifold from a M50B25. The 2.5L M50s have thicker runners that flow much better than M52 intake manifolds.

If you are chasing more power, consider an aftermarket aluminium intake manifold.

Injectors

Commonly used larger injectors that fit M50/M52 fuel rail (stock fuel pressure is 3.5bar, EV1 connector)

Siemens Deka 60lb 680cc @ 3.5 bar FI114961 - Spec Sheet

Siemens Deka 80lb 906cc @ 3.5 bar FI114992 - Spec Sheet

Fuel Pump

Fuel Pump Size Calculator - Stock fuel pump is approx. 105LPH

The below fit in-tank with minor modifications.

Walbro 255/460/525

DW300/400/440

Fuel Pressure Regulator

Does not need to be upgraded - aftermarket regulators typically have gauges which come in handy.

Fuel Rail and Fuel Lines

Stock rail and fuel lines are good for 800hp.

Fueling

Throttle Body

If using the M52 throttle body on the M50 manifold a spaccer/flange should be used to prevent boost leaks.

Idle Control

The ICV in stock form isn’t very securely attached to the M50 intake manifold. The connector between the ICV and the manifold is one of the major culprits for boost leaks. The ICV port on the manifold can simply be blocked off and epoxied shut. On low boost levels the ICV can be retained.

Intercooler + Piping

The typical intercooler core size used is 600 x 300 x 76mm, this is a fairly standard universal intercooler sizing. There is enough room next to the chassis rails for 3” tubing. A suitable route can be made from universal intercooler piping kits, however there are companies that make mandrel bent piping for easy installation.

Electronics

ECU

Bosch Motronic 3.3.1 aka Red Label 413

M50B25TU

The M50B25TU uses a Bosch Motronic 3.3.1 (Red Label 413) DME. This ECU can be tuned for boost however as it is OBD1 protocal, the logging and Diagnostic Trouble Code reporting is highly limited.

The go-to ECU for all M50B25TU turbo builds is the Link E36X Plug and Play ECU. This unit simply replaces the stock unit without any wiring.

Siemens MS41.0 (MS41.1/MS41.2)

M52

All M52s come with a variant of the Siemens MS41.0 DME. Newer versions such as MS41.1 or MS41.2 are physically identical and interchangeable - similarily the software version is also interchangeable between the variants.

This ECU can be tuned for boost and is adequate for low/medium boost levels. The MAF will need to be upgraded and a suitable tune needs to be implemented.

Unfortunately Link does not make a PNP ECU for the M52, however there are others that do such as VEMS, kdFI etc. To use the Link E36X on a M52, replace the M52 harness with an M50B25TU harness and use the sensors from the latter.

Link G4X BMWLINK – E36X PNP for M50B25TU

LINK G4X E36X

The Link E36X is the recommended option for all M5x engine builds. Using the M50B25TU loom and coresponding sensors, this ECU is plug & play for all M50s and M52s.